by admin | Nov 14, 2018 | News

The new HS Series (High Speed Washing Machines) are the perfect combination of versatility, reliability, strength, ease of use & innovation.

Designed to satisfy a wide range of customers’ requirements.

The HS Series, with the capacity of 8 to 55 KG, are recommended for hospitals, clinics, nursing homes & hotels.

All washing machines are equipped with:

- Fully programmable & user friendly computer.

- Fully controlled soaps pump.

- Possibility to create and change programs on a key.

- Speed management and the lap/pause ratio of the basket.

- Intelligent management of water level.

- No need to specific foundation for Installation of machines.

- Equipped with electric & steam heating system (direct & indirect).

by admin | Nov 14, 2018 | News

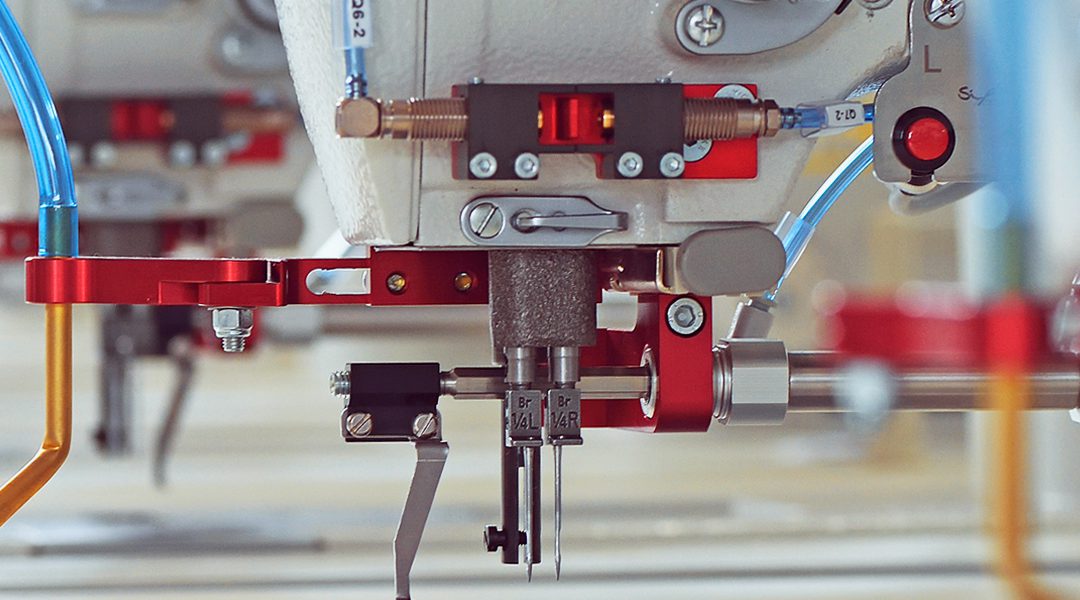

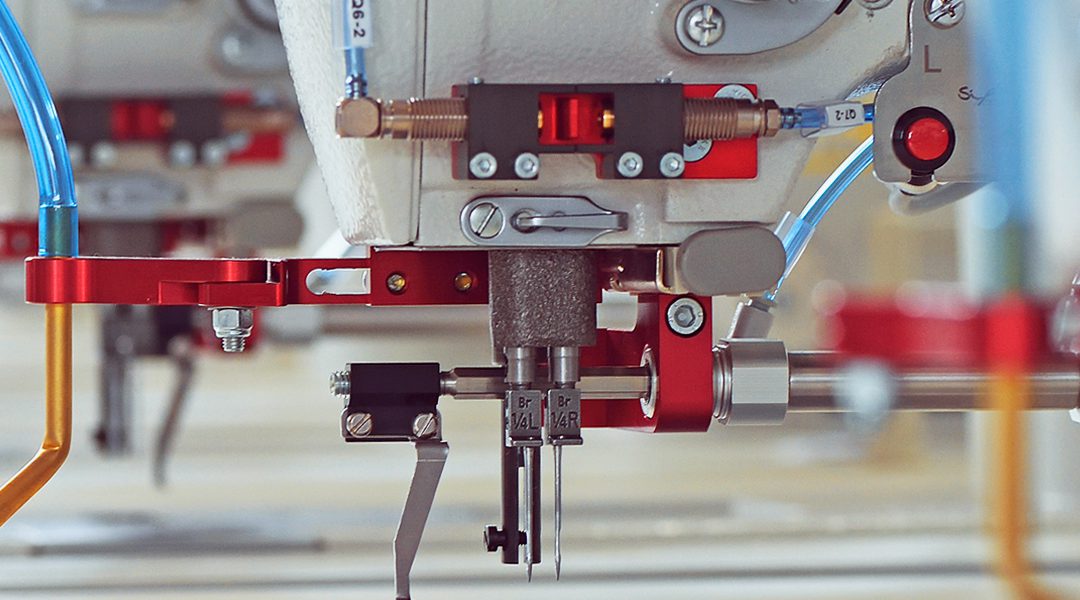

Fully automatic programmable pocket setter unit for Jeans.

PS342-FG2SIP is an automatic workstation for pocket folding and attaching in one operation.

Equipped with modular double sewing heads and cold folding group. Cold folding device is the unique solution for stretch denim fabric.

User doesn’t need to utilize any pocket pressing unit. The two sewing head work at the same time.

- Extra productivity of 25% compared with single head pocket setter unit.

- Modular concept of pocket setter unit with the possibility to join or split the second sewing head shifting stacker device between the units.

- Two sewing heads mean two different threads for needle and for bobbin cases.

- No skill workers and helpers to manage the pocket pressing unit, with saving of area, energy and generally reduction of the running cost.

- Large-capacity memory capable of storing bulky data, up to 512 programs, 500,000 stitches.

- Multi color touch screen 5.6” programmed for multi languages.

- Lowest running cost. Convenient access to outsource for standard spare parts at the best price and delivery.

- Average daily production 8 working hours: 1300 pairs of Jeans with regular pocket size.

by admin | Nov 14, 2018 | News

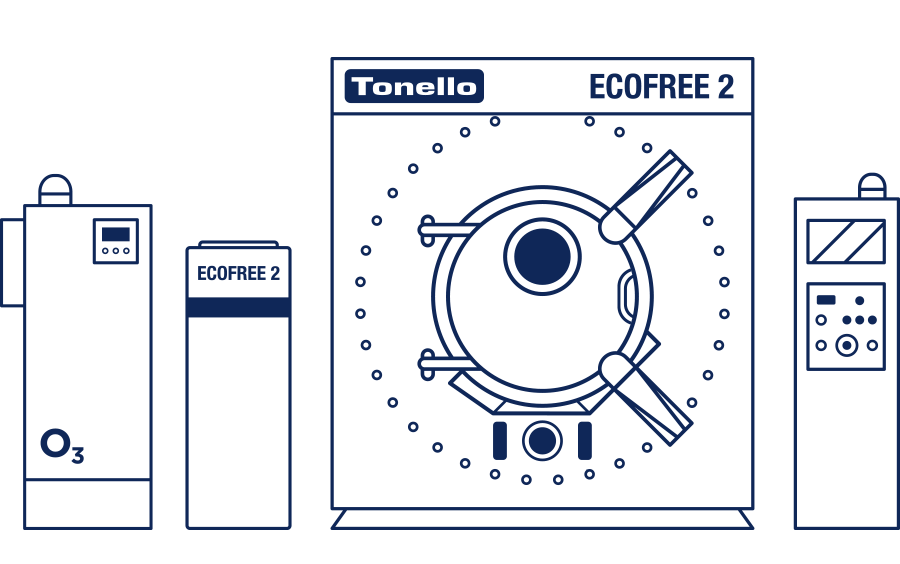

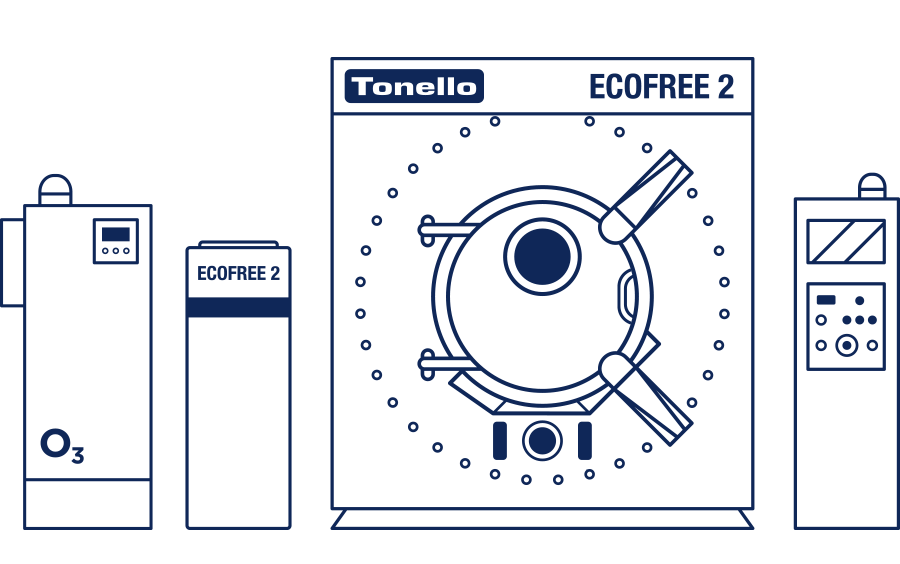

THE ALL-IN-ONE SYSTEM: EVERYTHING YOU NEED IN A SINGLE MACHINE

A single machine for performing all the finishing operations on the garment. This is the path that we have chosen to tangibly respond to the market’s most sophisticated demands, with an approach oriented towards sustainability and transparency and of course flexibility.

Because the ‘system’ has been created specifically in order to adapt to the most diverse necessities.

Our all-in-one system has become a reality with the arrival of ECOfree 2 being added to the already proven NoStone®, Core, and Up.

The system saves energy, reducing water and chemical consumption, cutting down processing times and total production costs, respecting the environment, reducing manual labor and protecting the health of operators.

- ECOfree 2 is the latest washing technology using ozone in the water and ozone in the air, the definitive treatment. Three systems in one, to guarantee the best performance on the garment, fewer manual operations and a huge reduction in water and chemical consumption. With ECOfree 2 the unstoppable finishing revolution continues.

- NoStone®, developed in collaboration with Levi Strauss and first prize winner at ITMA 2015, allows obtaining a stone-washed effect without using pumice stone (and therefore without pumice’s disadvantages, both economic and environmental). Other pluses include reduced manual labor and increased safety, as well as less water needed for purification and no more sludge to dispose of.

- UP, optimizes garment washing, reducing the bath ratio (LR 2: 1) to levels never seen before. It also drastically reduces energy consumption, reducing processing times and costs.

Finally, Core, which permits creating effects and applying products to garments, increasing performance and reducing water consumption by up to 96%. Impressive savings in product use and shorter processing times are the other benefits.

Recent Comments